From Sketch to Endorsement

Since our founding in Detroit in 2013, Detroit Watch Company has remained dedicated to one vision: timeless design paired with high-quality Swiss mechanical movements. Each timepiece is meticulously hand-assembled, adjusted, and tested in our Michigan studio, ensuring both precision and artistry.

As our vision continues to evolve, we create original luxury timepieces that embody our passion for design that honors l' héritage of Détroit, a city founded by a Frenchman, Antoine de la Mothe, sieur de Cadillac, whose legacy continues to inspire our craft.

Assembly

Every timepiece begins with a specific movement followed by the design of each component comprising the case, dial, hands, and crown all exclusive to Detroit Watch Company timepieces, ensuring originality in every detail.

Our sketches and technical drawings are transformed into reality with our trusted specialists before returning all parts to us for final assembly.

Each automatic movement is cased, every component installed, and fully adjusted and tested by Detroit Watch Company. This hands-on process gives us complete control over quality and allows us to uphold the highest standard of craftsmanship.

Because we insist on such precision and attention, our collections are created only in limited quantities each year. This dedication not only preserves exclusivity, but also allows us to craft future limited editions of timepieces that embody authenticity, artistry and timeless design.

Mechanical Movement

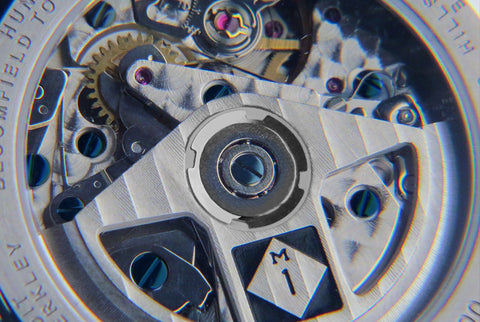

We chose mechanical movements for their beauty, intricacy, and the timeless connection they create between the watch and its wearer. To own a mechanical watch is to carry a miniature work of art on your wrist with hundreds of finely crafted parts working in harmony, powered simply by the natural rhythm of your movement.

With each subtle motion of the wrist, the watch comes alive. The rotor, a finely weighted arc, captures this energy and winds the mainspring, ensuring the watch remains in constant motion.

Like all true automatics, each timepiece may also be wound by hand, offering a ritual as timeless as watchmaking itself.

Every movement is finished with functional artistry. Synthetic rubies, precisely placed and lubricated, minimize friction on hardened steel pivots, extending the life and accuracy of the gear train. Each detail is designed not only for performance but for longevity, reflecting the enduring craft of Swiss horology.

In our collections, we feature Swiss ETA and SELLITA automatic movements, trusted by collectors worldwide for their reliability and refinement.

For those seeking rarity, we also offer a custom built Valjoux 7750 chronograph caliber, produced exclusively for Detroit Watch Company and offered in limited numbers.